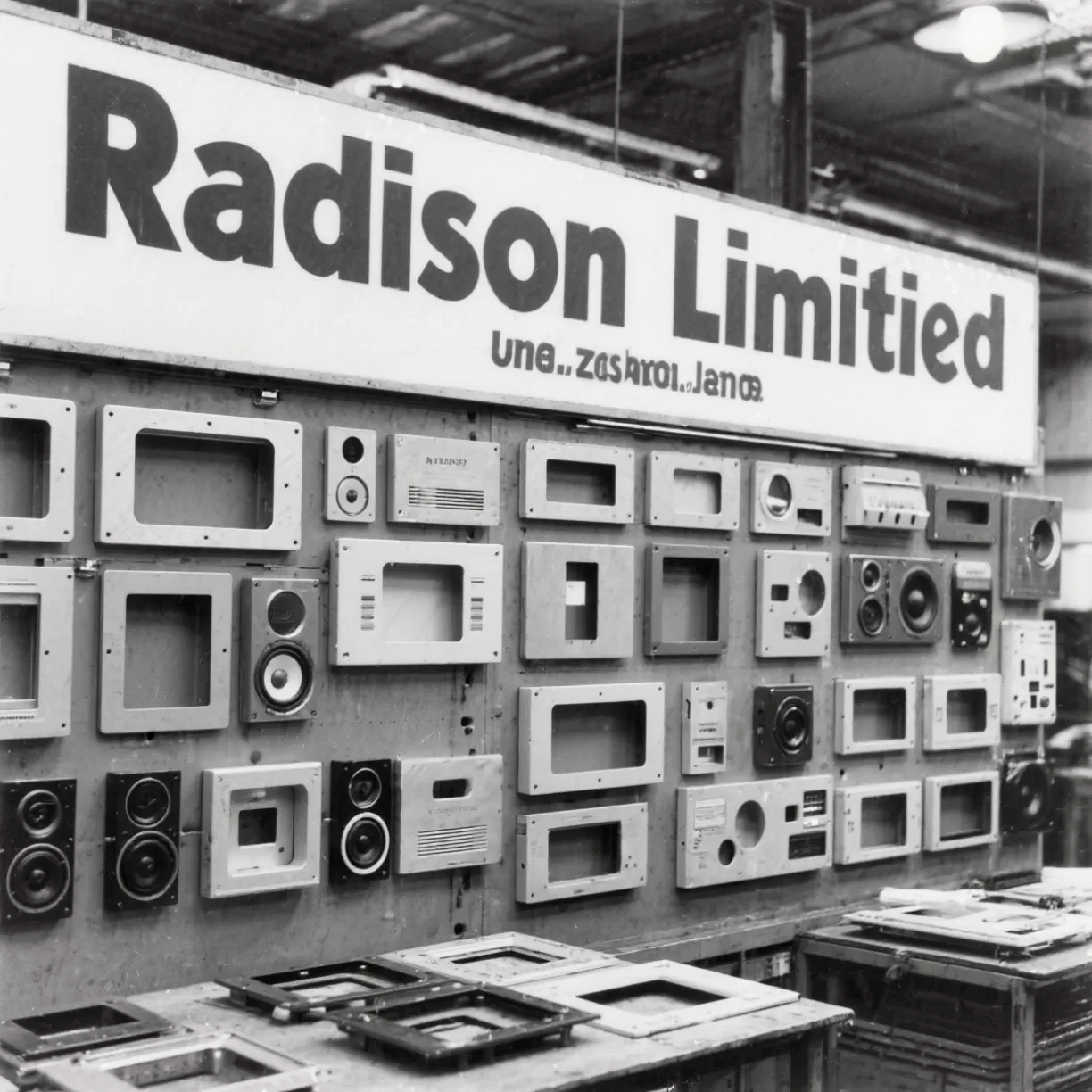

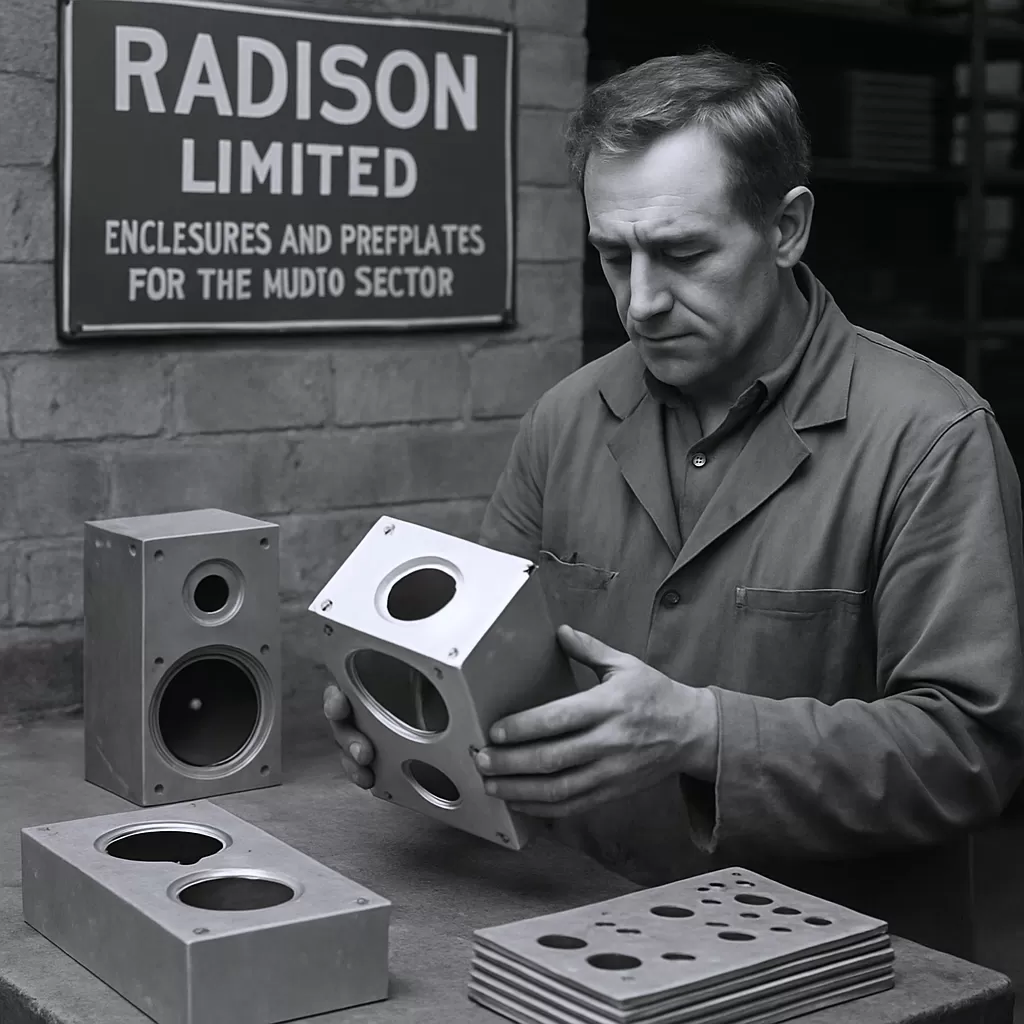

Radison Limited emerged from a vision to revolutionize precision manufacturing and luxury metal finishing. Founded with a commitment to excellence and innovation, the company has grown from a small specialized workshop to a leading provider of premium metal fabrication services. Our journey began with a focus on aluminum processing and has expanded to encompass a wide range of advanced manufacturing capabilities, setting new standards in quality and craftsmanship.

Radison Limited was founded by entrepreneur Michael Radison in a small workshop in Ontario, Canada. Starting with basic aluminum fabrication services, the company focused on serving local construction and manufacturing clients with high-quality custom metalwork and precision machining services.

The company made its first major investment in advanced anodizing equipment, allowing Radison Limited to offer premium surface finishing services. This marked the beginning of our specialization in luxury metal finishing and our reputation for exceptional quality began to spread throughout the region.

Radison Limited expanded its facility and workforce, adding specialized departments for precision machining and custom fabrication. The company secured its first major contract with a luxury automotive manufacturer, establishing our presence in the high-end manufacturing sector.